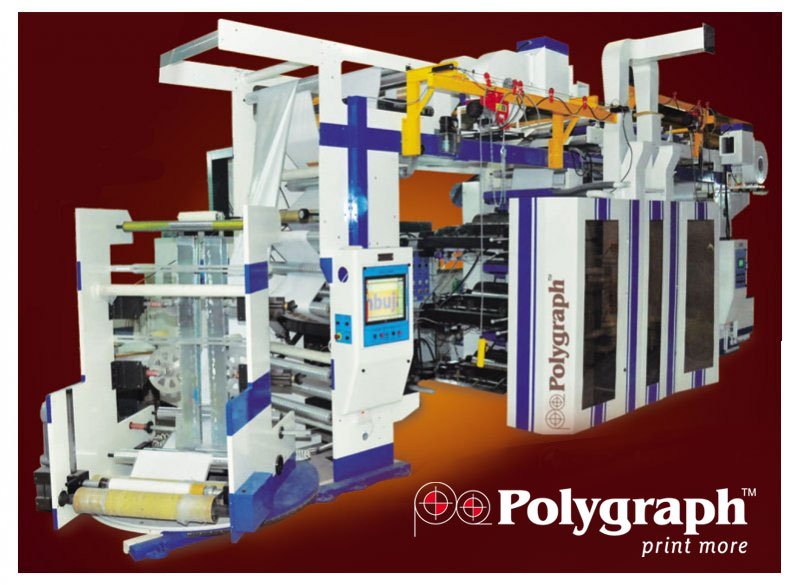

Stack-Type Flexographic Printing Press- Woven Fabric

FEATURES

• Speed 140 mpm• 5 Motor Drive tension control system with Programmable digital ac drives

• Hydraulic lift off/on of printing cylinders & Continuous rotation of anilox roll driven by motors

• Inline turn table gussetting system

• Web Video System

• Chambered doctor blade system

• Ceramic anilox rolls

• Silent & powerful drying & exhaust system

• Inline perforation system

Technical Specification:

- Opto Electronic Web Guiding System

- digitally controlled web guiding for precise guiding of web

- Automatic Tension Control System

Load Cell feed back control provided on Unwind, Infeed, Outfeed & Rewind Station to maintain uniform tension throughout the entire roll.

|

5 Motor Drive (5MD) technology for: |

|

1. Unwind Station |

|

2. In feed Station |

|

3. Main Printing Station |

|

4. Out Feed Station |

|

5. Rewind Station |

|

|

Hydraulic System

Provided for continuous rotation of Inking Rollers and Auto Lifting of Plate Cylinders when machine is printing in OFF mode. This prevents drying of inks on the Anilox Roller.

Chamber Doctor Blade System

For uniform & controlled ink supply on the Anilox Roll.

Ceramic Anilox Rolls

Higher mesh laser engraved Anilox rollers for precise transfer of ink to achieve better and enhanced print quality.

Double Diaphragm Ink Pumps

Air operated pumps for controlled circulation of ink between Ink Tank & Chambered Doctor Blade.

Web Video System

Web Inspection System, equipped with high quality color camera, Quick Zoom & Split Screen, mounted on motorised

traverse bar to monitor complete print at all speeds.

Pneumatic Shaft

Provided on Unwind for quick and easy loading and unloading of the Parent roll.

Pneumatically operated Nip Rollers

to maintain uniform & precise tension at printing, infeed and outfeed stations.

Inline Turn Table Gussetting System (Off Set)

to gusset the fabric, inline after printing with turn table system.

Perforation System

for inline perforation on the fabric.